Gearing Up Procurement Teams to Fight Inflation

TABLE OF CONTENTS

Ignited by the COVID-19 pandemic, inflation has been part of the global industrial landscape for over two years now. From countries implementing pandemic-induced mandates to massive labor shortages due to the Ukrainian Crisis, inflation rates are at an all-time high and not a single commodity has been able to escape the price pressure. According to the National Statistics Office (NSO), inflation reached a record-breaking 7.7% while food price inflation surged to 8.38%.

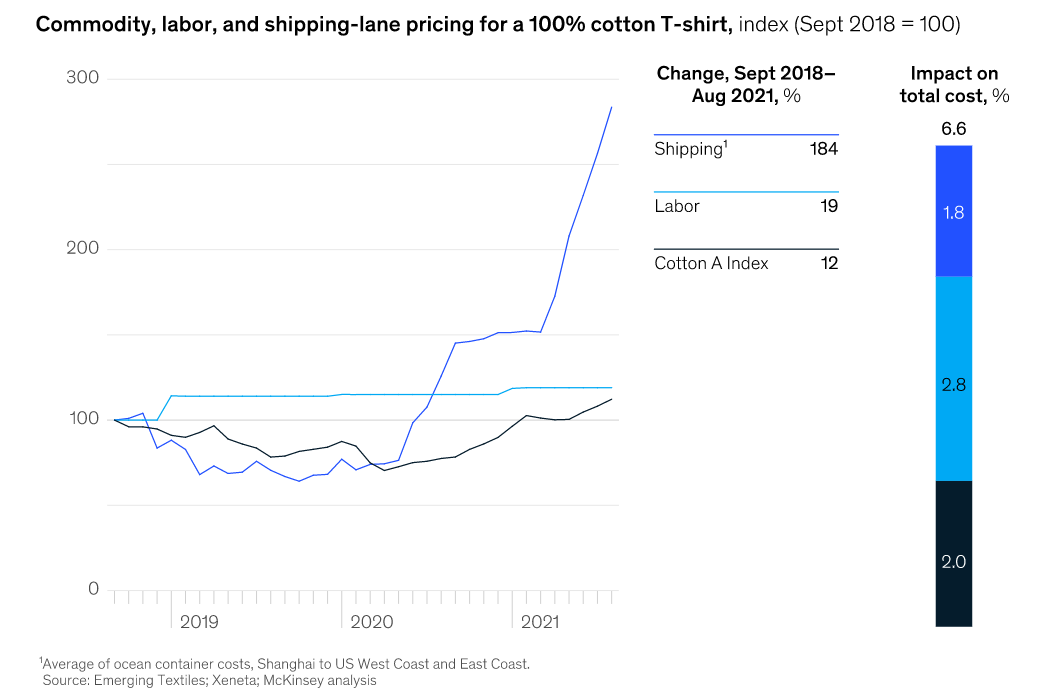

These turbulent conditions have triggered price pressures and subsequently, influenced procurement power for organizations. As prices rise, businesses that traditionally kept procurement operations at bay are now embracing procurement teams for desperate attempts to maintain economic balance. Higher prices have made it difficult for businesses to identify price variance for commodities set by suppliers to offset inflation. The price fluctuation incorporates the supplier’s cost for labor, materials, and freight, which is repeated across each tier of the supply chain. The graph below gives a detailed view of price history which helps determine a reasonable price.

How Can Procurement Teams Make Most Impact?

For procurement teams to defend against inflation, leaders need to redesign their strategies and upgrade approaches. While savings can still be achieved, shifting focus to using internally focused levers like process optimization, demand management, specification change, and supply chain reconfiguration, would help mitigate future risks. Mentioned below are some points that can help businesses rapidly adapt to the inflationary world.

- Prioritizing Categories on the Basis of Exposure

Indexing categories on the basis of index trends and futures can help segregate valuable categories. Placing different weightages to price changes and market constraints leads to determining inflation expectation. This inflation expectation helps in accurately assessing revenue management across categories, limit unnecessary erosion, and sustain value-based margin levels. Businesses can also build internal infrastructure and adjust inventory to drive operational efficiency and future-proof against the next inflationary cycle.

- Uncovering Should Costs

Should cost modeling is a powerful estimation tool that can empower procurement teams to determine final cost and advance negotiations with suppliers. Procurement teams can aggregate historic and real-time data to expand key cost drivers and develop meaningful insights that can add value to business. Such cost modeling infrastructure is extremely valuable to understand the entire cost structure including profit, labor, overhead, and equipment, eliminate maverick spending, and provide a solid base for negotiations with suppliers to find mutually beneficial solutions.

- Responding to Suppliers

Post-analyzing the expected commodity price and inflated categories, crafting appropriate responses to suppliers supports the procurement team’s position against inflation. Addressing short-term and long-term volatility challenges such as optimizing supplier footprints, strategic inventory stockpiling, and cross-industry collaboration for commodity exposures, can help improve resilience. Here are some points on how to approach potential supplier negotiation sessions.

1. Leverage Existing Partnerships Long-standing partnerships can significantly help in getting the best price from suppliers. In the longer run, such practices minimize risk and enhance cost resiliency as compared to passing on costs to consumers which can result in negative brand perception and market-share loss.

2. Consider Price Raise Backed by Rigorous Facts Utilizing should-cost models to negotiate with suppliers can give you the right price, given the market conditions. While multiple commodities are experiencing price increase, using fact-based analysis to highlight specific areas of cost increment can minimize inflationary risk.

3. Pursue Win-Win Negotiations While fact-based analysis can help determine an estimated commodity price, procurement teams can also resort to partly increasing price for customers while building strategic-supplier relationships for the future.

4. Discover New Suppliers Engaging with a new pool of suppliers can be highly effective to procure commodities at better cost/service. Strategic review of existing contracts and suppliers also helps in identifying non-incumbent suppliers or high-price offering suppliers that can inflate the overall procurement spend.

5. Improved Procurement Visibility Breaking down data silos and unlocking transparency across procurement spends can enable procurement teams to improve forecasting and reporting. Using smart procurement solutions gives an edge in understanding the entirety of the procurement process right from raising the purchase request (PR) to tracking orders, invoices, and contracts, at a single platform. Procurement teams can also take complete control of procurement spends across categories to adjust budgets, mitigate action plans and highlight any exposure across the supply chain.

Conclusion

While there’s no cure for inflation, procurement teams can resort to taking a proactive approach which involves detailed market analysis, improved supplier relationships, fact-based negotiations, and inventory management. With the right approach, businesses can revamp their price-negotiation potential and unlock long-term resilience against inflation.

Procol is a next-generation procurement software that is designed to give procurement teams 100% visibility and control of their spend. From automating purchasing workflows to improving operational efficiency, Procol has helped organizations realize unmatched ROI and savings for their business. Want to know how we’ve helped leading companies? Book your slot today.

Get a Free Demo

We'd love to hear from you. Please fill out this form to schedule a demo with us. You can also give a call on +91 76666 82222