Procol • April 15, 2025

Procurement Software In The Chemical Industry

Procurement Software In The Chemical Industry

The procurement process has undergone a significant transformation, with technology having an important role.

Businesses have been trying hard to increase transparency and efficiency and reduce time delays. It leads us to an inevitable conclusion — enterprises are slowly but surely, switching over to software-based procurement automation.

According to Statistica, the global procurement software market is likely to expand at a growth rate of 4% from 2015 to 2025.

This blog will help you understand the procurement software in the chemical industry.

What Is Procurement Software?

Procurement software is a class of software applications that automate and improve soliciting, evaluating, and approving suppliers and managing supply contracts.

Procurement software also provides an organisation’s management with easy-to-understand reports about all procurement activities.

The procurement system helps organisations reduce costs by automating the entire sourcing cycle from request to fulfilment. These applications eliminate manual paperwork and help businesses connect with more vendors by streamlining processes.

Core Functions Of Procurement Software In The Chemical Industry

The procurement software market is expected to grow at a CAGR of 10.2 per cent. Now, let’s see the core functions of the procurement system in the chemical industry.

-

Selection Of Preferred Suppliers: This function narrows down the selection of suppliers based on specific criteria set by the user. It also provides an overview of all available suppliers to facilitate this process.

-

Submission Of Orders: Once the procurement system has been set up with preferred suppliers, it allows users to send in requests for bids or quotes. These requests can be sent to multiple suppliers simultaneously, making it easier and faster to secure required supplies.

-

Viewing Financial Information: This feature offers detailed financial information about each order placed, including cost breakdowns and profit margin projections. It helps companies avoid overspending on supplies or hiring unnecessary staff.

-

Information Management: The system helps business owners organize all relevant information regarding their suppliers, including contact information and past performance evaluation reports. It can help when finding new suppliers and deciding which people are worth doing business with.

-

Order Management: Procurement software helps you manage your orders, procure goods, and track the goods that have been shipped. The procurement system’s order management function helps you maintain a record of all the purchases made by your company. The process also enables you to know the status of pending orders from suppliers and the status of shipping information.

-

Inventory Management: The chemical industry deals with a lot of different chemicals and products. Your procurement system should be able to manage these products in a very efficient way to meet your customers’ needs. Inventory management is a crucial part of any business, and it will help you keep track of what is coming in and going out of your business. You can also set up alerts so that if there is any shortage or problem with the supply chain, you can immediately get it fixed. This way, you will never run out of stock, and your customers will always have their products on time.

5 Procurement Problems In The Chemical Industry

From delivering value to multiple stakeholders to finding suitable suppliers to managing risk and compliance, procurement automation in this industry has its work cut out for them.

Here are five common problems faced by procurement in the chemical industry:

-

Complex And Global Supply Chains: Chemical companies have numerous suppliers, often spread across different regions or countries. They also have many internal stakeholders who need to collaborate to ensure that purchasing decisions align with the company’s long-term goals.

-

Supplier Management: Chemical manufacturing involves numerous types of raw materials and ingredients from diverse suppliers. Procurement teams must manage large supplier bases while balancing cost, quality, delivery, and service requirements.

-

Regulatory Compliance: In addition to standard contracts and terms, procurement teams must also negotiate safety requirements and compliance certificates with suppliers.

-

Raw Material Availability: Suppliers’ ability to deliver against orders is often based on their inventory availability. If they cannot supply the goods when needed, this can lead to costly supply chain disruptions that impact customer satisfaction levels and profitability.

-

Safety Risks And Stringent Regulations: The chemical industry is subject to several regulations designed to protect people and the environment. For example, REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) requires companies to register all substances they manufacture or import into Europe. In addition, chemical companies are at risk of handling hazardous materials that can pose safety risks if not appropriately handled by suppliers.

Wrapping Up

Chemical companies are under tremendous pressure to deliver the best quality product at a lower cost quickly.

Procurement software helps with this by allowing companies to streamline their logistics process and, by doing so: increase efficiency.

There is a wide range of options for which features will have the most significant impact on increasing efficiency and making procurement systems more beneficial for companies within the chemical industry.

Explore more from Procol

Discover expert tips, how-to guides, industry insights, and the latest procurement trends.

What is Procure-to-pay (P2P)? An Ultimate Guide

Procure to pay is the process from procurement of materials needed...

Best eSourcing Tools: Top 10 eSourcing Software in 2025

Discover top 10 e-sourcing tools and esourcing platforms necessary for efficient...

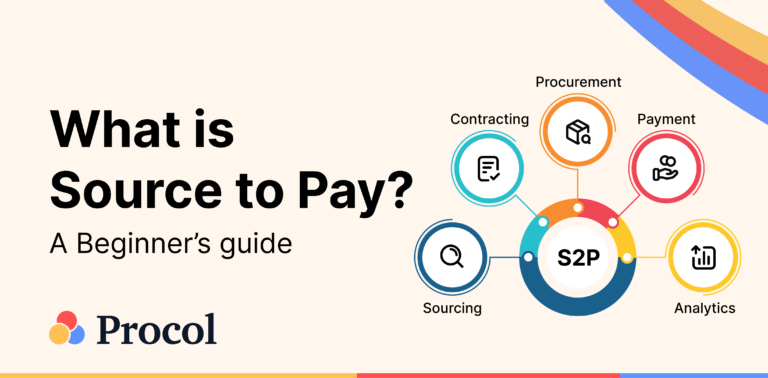

What is Source-to-pay in 2025? An Ultimate Guide

Source to pay is the process of sourcing vendors to procure...